Film Slitting

Film Slitting

Multiple Substrate Inspection Slitter Rewinder

Benefits

- Unique Finishing capabilities on a multitude of unsupported and supported Films, Foils, Papers and Light Board, utilising 1 machine for a wide variety of substrates and finishing applications

- Modular design can be reconfigured for a variety of specialist finishing applications such as booklets, ticket & tags, wrap & colour chip labels

- Intelligent taper tension control system achieves a perfect rewind profile every time

- Job memory facility enables your operator to use pre-loaded job settings in a matter of seconds

As our machines are designed and built in-house, we have the unique ability to tailor equipment to meet the specific requirements or requests of our customers.

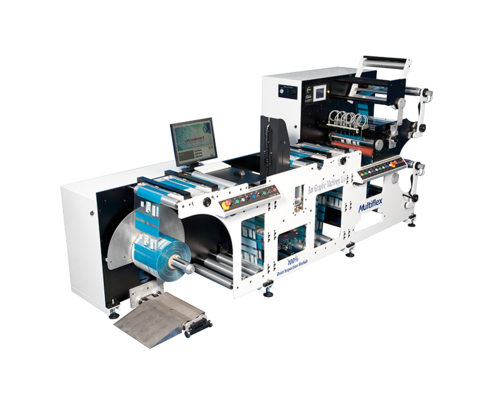

BGM Elite 450 / 550 Multiflex Mutliple Substrate Inspection Slitter Rewinders

Specifically designed as a multi-purpose multiple substrate inspection slitter rewinder, the BGM Multiflex can finish a wide range of unsupported and supported Films, Foils, Label stock, Papers and Light Board from substrate thicknesses of 11 microns and upwards with a dynamic performance at speeds of up to 300 m/ min.

The machine can accommodate a wide variety of automatic web inspection control systems, from sensor free MMLD, through to full 100% Inspection control. Due to the unique design of the fully modular Multiflex, a number of manufacturers inspection systems are retrofittable, offering detection of print errors such as text or ink irregularities, scratches, registration errors or colour variations. Fully automated workflow systems from press to rewinder, removal of waste whilst still inspecting the web are also achievable.

Primarily designed for flexible packaging, film and label applications, the Multiflex modular design can be reconfigured for a variety of specialist finishing applications, such as booklets, ticket & tags, wrap & colour chip labels

Benefits

- Unique Finishing capabilities on a multitude of unsupported and supported Films, Foils, Papers and Light Board, utilising 1 machine for a wide variety of substrates and finishing applications

- Modular design can be reconfigured for a variety of specialist finishing applications such as booklets, ticket & tags, wrap & colour chip labels

- Intelligent taper tension control system achieves a perfect rewind profile every time

- Job memory facility enables your operator to use pre-loaded job settings in a matter of seconds

As our machines are designed and built in-house, we have the unique ability to tailor equipment to meet the specific requirements or requests of our customers.

download brochure